-

Introduction

-

Introduction

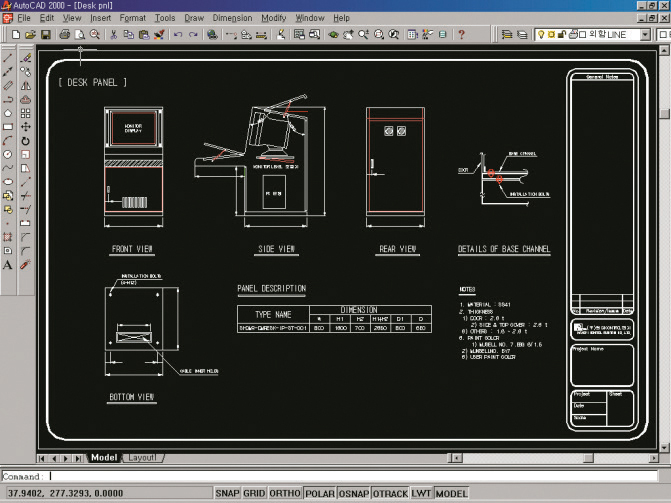

Products

-

-

Products

-

Introduction

Products

-

- Safety Warning System

- Electric Resources

- Work process

-

Supprot

-

Introduction

Products

-